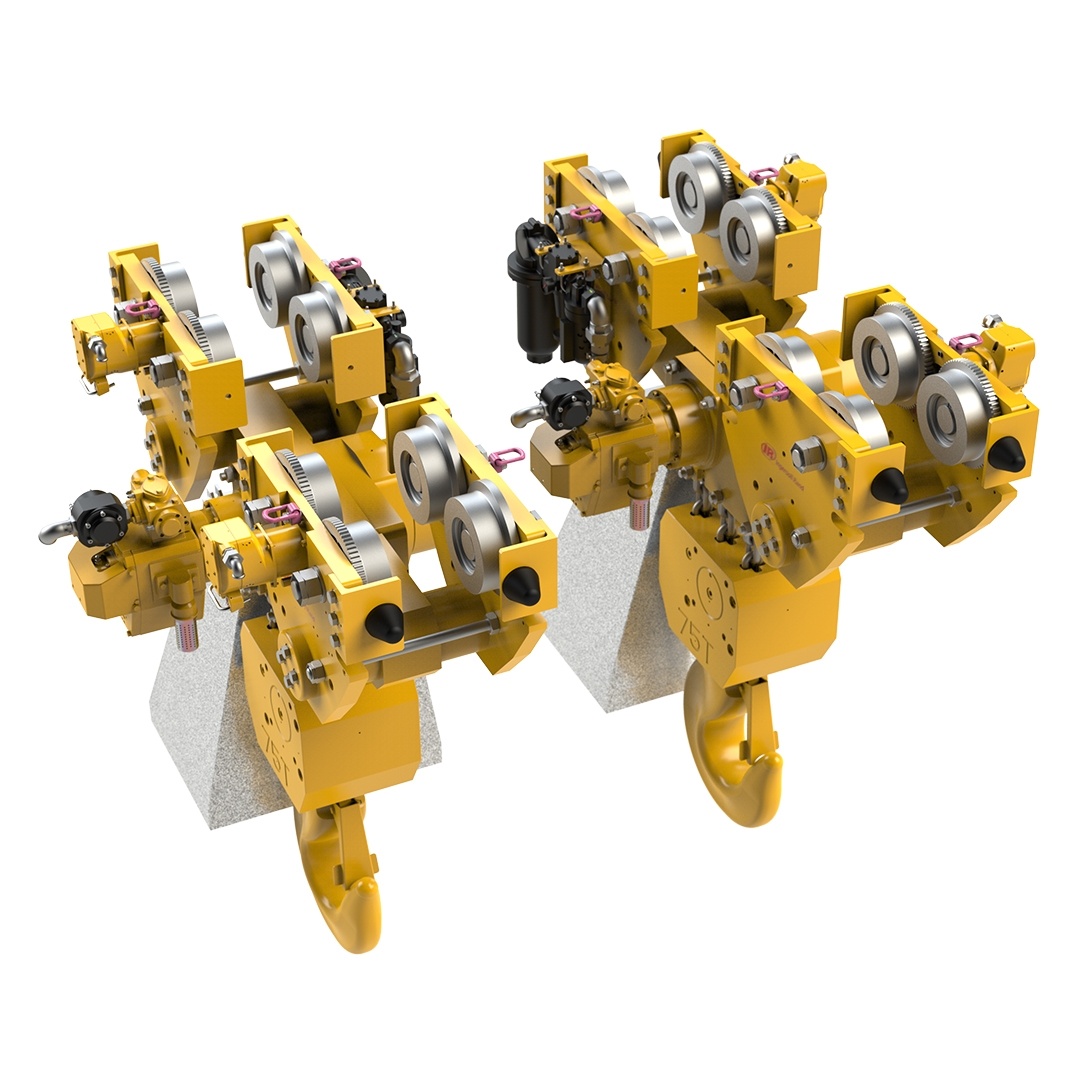

BOP Handling Systems

- Steel or cast iron construction with 5:1 design factor on load-bearing parts

- Systems feature a new modular “platform” design that can accommodate either gear or piston air motors, as well as hydraulic versions

Product Overview

Ingersoll Rand has designed, manufactured, and serviced hundreds of Blowout Preventer (BOP) Handling Systems for all the major drilling contractors and oil companies in the industry. Our familiarity with this complex and critical lifting application enables us to provide the type of equipment, engineering support, and certifications that these projects require.

- Automatic failsafe multi-disc brake on hoist and trolley

- Corrosion resistant load chain, marine paint and bolting

- Capacities from 25 to 250 metric tons

Product resources

Pneumatic Hoist Sub-Assembly

| Series | Lifting capacity ton | Motor type | Min headroom mm | Lifting speed at rated load m/min | Lowering speed at rated load m/min | Weight kg |

|---|---|---|---|---|---|---|

| Liftchain - BS | 25 - 200 | Gear motor | 1043 - 1960 | Up to 1.6 | Up to 2.5 | 13300 |

| Liftchain - BHS | 50 - 150 | Piston motor | 1043 - 1520 | Up to 1.2 | Up to 1.8 | 6400 |

| Liftchain Low - LBS | 25 - 50 | Gear motor | 670 - 775 | Up to 1.8 | Up to 1.3 | 1700 |

| Liftchain Ultra Low - ULBS | 100 - 250 | Gear motor | 377 - 905 | Up to 1.4 | Up to 3 | 17000 |

Pneumatic Trolley Sub-Assembly

| Series | Motor type | No. of wheels per hoist | Std. flange adjustment mm | Max beam bottom flange thickness mm | Wheel loading per pair kg | Max travelling speed m/min |

|---|---|---|---|---|---|---|

| Liftchain - BS | Gear motor | 4 - 16 | 130 - 360 | 40 - 102 | 6250 - 18750 | Up to 15 |

| Liftchain - BHS | Piston motor | 8 | 160 - 360 | 40 - 102 | 6250 - 18750 | Up to 12 |

| Liftchain Low - LBS | Gear motor | 4 | 140 - 314 | 40 | 6000 - 12500 | Up to 15 |

| Liftchain Ultra Low - ULBS | Gear motor | 8 - 16 | 200 - 360 | 76 - 102 | 9375 - 18750 | Up to 12 |

Hydraulic Hoist Sub-Assembly

| Series | Lifting capacity ton | Min headroom mm | Lifting speed at rated load m/min | Lowering speed at rated load m/min | Working pressure bar | Weight kg |

|---|---|---|---|---|---|---|

| Liftchain - BS | 25 - 200 | 1043 - 1960 | Up to 2.25 | Up to 2.25 | 125 - 195 | 13100 |

| Liftchain Low - LBS | 24 - 50 | 670 - 775 | Up to 2.8 | Up to 2.8 | 130 - 150 | 1750 |

| Liftchain Ultra Low - ULBS | 100 - 250 | 615 - 905 | Up to 2.3 | Up to 2.3 | 170 - 185 | 17000 |

Hydraulic Trolley Sub-Assembly

| Series | No. of wheels per hoist | Std. flange adjustment mm | Max beam bottom flange thickness mm | Wheel loading per pair kg | Max travelling speed m/min |

|---|---|---|---|---|---|

| Liftchain - BS | 4 - 16 | 150 - 360 | 40 - 102 | 6250 - 18750 | Up to 15 |

| Liftchain Low - LBS | 4 | 140 - 314 | 40 | 6000 - 12500 | Up to 15 |

| Liftchain Ultra Low - ULBS | 8 - 16 | 160 - 360 | 76 - 102 | 9375 - 15625 | Up to 12 |

Services and support

Whether it is choosing the right tool for the job, improving technical and operational knowledge or product maintenance and warranty, HES is here to help.

Tell me moreEnquire now

Want to know more about the range? Our product team are on hand to support you with your requirements. Speak to our team today.

Enquire